How to add value to MSA optical transceivers?

2017-07-05

Optical fiber is the transport medium that has emerged to accommodate the expected long-term growth in the communications industry. Taking advantage of the wide bandwidth — the principal advantage in optical communications systems — requires stringent control and monitoring of various optical fiber related parameters such as temperature, average laser power, and extinction ratio.

The evolution of today's optical transceivers and transponders is driven by multi-source agreements (MSA), which establish a standard for optical and electrical characteristics, module form factor, and pin functions of optical transmitters and receivers.

In more recent years the emerging MSAs have stipulated that optical system designers incorporate various diagnostic functionality into transceivers, as well as the traditional monitoring and control functions. These requirements are in addition to an overall drive to continue to minimize size and cost of the optical transceiver design.

Engineers whose core competence and background is in optical fiber systems now struggle to understand how to best implement analog and digital control loops, and provide diagnostic information via a 2-wire I2C-based communications bus.

Furthermore, they must ensure that their designs continue to adhere to the fast moving and evolving optical transceiver specifications.

The ongoing development and evolution of optical MSA specifications such as XFP, XENPAK, XPAK and SFF-8472 present today's optical system designers with a unique set of challenges which must be addressed in an increasingly competitive market segment.

The design, test, and manufacture of optical transceivers can be greatly simplified by a single chip, reprogrammable data acquisition solution that can provide control, monitoring, and diagnostic functions in MSA optical transceivers.

To date the primary challenge for designers has been maintaining constant optical power (Pav) and constant extinction ratio (Er) with changes in temperature — these parameters are a measure of signal integrity and transmission distance. In addition, designers must include digital diagnostic monitoring to comply with MSA specifications.

A re-programmable, single-chip precision data acquisition system with microcontroller in a small footprint can simplify this design challenge. Addressing both the optical monitoring and control design task, this approach allows designers the flexibility to easily incorporate additional features, thus adding value to their optical transceiver or transponder module.

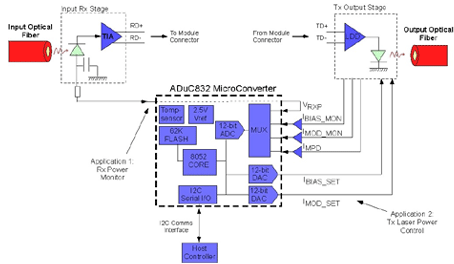

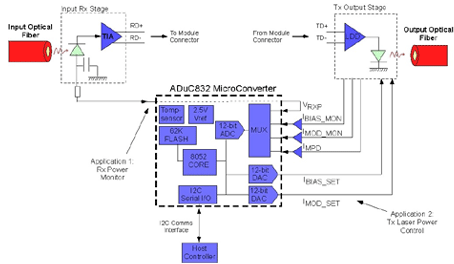

Let's examine a typical optical module. On the receive side, data is fed directly from the trans-impedance amplifier (TIA) to an external ASIC or serializer/deserializer (SerDes). On the transmit side, data is fed to a high-speed laser diode driver (LDD), which drives the laser (e.g. a DFB laser at 1310 nm) and modulates the data-signal onto it. A single-chip, such as Analog Device's MicroConverter, can take care of Pav and Er control, and also feed digital diagnostic information back to the host.

In this case, the ADCs, 8052 controller and DACs are integrated on a single mixed-signal device, the ADuC832. The ADCs and DACs are used to control Pav and Er. This approach takes full advantage of the analog peripherals, while offering users the flexibility to implement either conventional closed-loop control via a proprietary algorithm or feed-forward control via a look-up table.

In addition the MicroConverter enables users to feed diagnostic information back to the host via its I2C interface as defined by MSA requirements.

A typical MSA requires that five parameters be available from a module as follows:

TX bias current (accuracy >= 2?A)

TX optical power (accuracy >= 0.1 ?W)

RX optical power (accuracy >= 0.1 ?W)

Transceiver supply voltage (accuracy >= 100 ?V)

Transceiver temperature (accuracy >= 3C)

This can easily be achieved by using four 12-bit ADC channels to measure Vrxp, Ibias, Imod and Vdd, and a sensor to measure temperature. Results can be scaled or offset (vendor-specific) by the 8052 microcontroller before being transmitted to the host system via the I2C serial port.

Furthermore, users can compare these values to preset alarm and warning threshold levels to detect fault-conditions. Users have the option of monitoring additional parameters using the remaining four ADC channels. For more sophisticated transceivers the pulse-width modulated (PWM) outputs may be used to provide extra control channels, e.g. avalanche photodiode (APD) bias control or thermo-electric cooler (TEC) set-point control.

SFP+ module,SFP+ transceiver,bidi sfp,XFP module,XFP transceiver Which is good? First choice Fiberland!Thanks for your concern, to learn more about Fiberland, please enter Fiberland website: http://www.fiberlandtec.com/

The evolution of today's optical transceivers and transponders is driven by multi-source agreements (MSA), which establish a standard for optical and electrical characteristics, module form factor, and pin functions of optical transmitters and receivers.

In more recent years the emerging MSAs have stipulated that optical system designers incorporate various diagnostic functionality into transceivers, as well as the traditional monitoring and control functions. These requirements are in addition to an overall drive to continue to minimize size and cost of the optical transceiver design.

Engineers whose core competence and background is in optical fiber systems now struggle to understand how to best implement analog and digital control loops, and provide diagnostic information via a 2-wire I2C-based communications bus.

Furthermore, they must ensure that their designs continue to adhere to the fast moving and evolving optical transceiver specifications.

The ongoing development and evolution of optical MSA specifications such as XFP, XENPAK, XPAK and SFF-8472 present today's optical system designers with a unique set of challenges which must be addressed in an increasingly competitive market segment.

The design, test, and manufacture of optical transceivers can be greatly simplified by a single chip, reprogrammable data acquisition solution that can provide control, monitoring, and diagnostic functions in MSA optical transceivers.

To date the primary challenge for designers has been maintaining constant optical power (Pav) and constant extinction ratio (Er) with changes in temperature — these parameters are a measure of signal integrity and transmission distance. In addition, designers must include digital diagnostic monitoring to comply with MSA specifications.

A re-programmable, single-chip precision data acquisition system with microcontroller in a small footprint can simplify this design challenge. Addressing both the optical monitoring and control design task, this approach allows designers the flexibility to easily incorporate additional features, thus adding value to their optical transceiver or transponder module.

Let's examine a typical optical module. On the receive side, data is fed directly from the trans-impedance amplifier (TIA) to an external ASIC or serializer/deserializer (SerDes). On the transmit side, data is fed to a high-speed laser diode driver (LDD), which drives the laser (e.g. a DFB laser at 1310 nm) and modulates the data-signal onto it. A single-chip, such as Analog Device's MicroConverter, can take care of Pav and Er control, and also feed digital diagnostic information back to the host.

In this case, the ADCs, 8052 controller and DACs are integrated on a single mixed-signal device, the ADuC832. The ADCs and DACs are used to control Pav and Er. This approach takes full advantage of the analog peripherals, while offering users the flexibility to implement either conventional closed-loop control via a proprietary algorithm or feed-forward control via a look-up table.

In addition the MicroConverter enables users to feed diagnostic information back to the host via its I2C interface as defined by MSA requirements.

A typical MSA requires that five parameters be available from a module as follows:

TX bias current (accuracy >= 2?A)

TX optical power (accuracy >= 0.1 ?W)

RX optical power (accuracy >= 0.1 ?W)

Transceiver supply voltage (accuracy >= 100 ?V)

Transceiver temperature (accuracy >= 3C)

This can easily be achieved by using four 12-bit ADC channels to measure Vrxp, Ibias, Imod and Vdd, and a sensor to measure temperature. Results can be scaled or offset (vendor-specific) by the 8052 microcontroller before being transmitted to the host system via the I2C serial port.

Furthermore, users can compare these values to preset alarm and warning threshold levels to detect fault-conditions. Users have the option of monitoring additional parameters using the remaining four ADC channels. For more sophisticated transceivers the pulse-width modulated (PWM) outputs may be used to provide extra control channels, e.g. avalanche photodiode (APD) bias control or thermo-electric cooler (TEC) set-point control.

SFP+ module,SFP+ transceiver,bidi sfp,XFP module,XFP transceiver Which is good? First choice Fiberland!Thanks for your concern, to learn more about Fiberland, please enter Fiberland website: http://www.fiberlandtec.com/

RECENT BLOG POST

-

012019-10With the continuous development of 5G communication technology, 100G modules are gradually becoming popular. We know that there are many kinds of packages for 100G optical modules. From 2000 to now, the optical module package types have been rapidly developed. Its main package types are: GBIC, SFP, XENPAK, SNAP12, X2, XFP, SFP+, QSFP/QSFP+, CFP, CXP. In the fast-developing network era, some 100G optical modules avoid the risk of being eliminated, and upgraded and revised with the wave of the Internet, such as 100G CFP optical modules.

-

012019-101. What is the CWDM SFP? The CWDM optical module is an optical module using CWDM technology to implement the connection between the existing network device and the CWDM multiplexer/demultiplexer. When used with a CWDM multiplexer/demultiplexer, CWDM optical modules can increase network capacity by transmitting multiple data channels with separate optical wavelengths (1270 nm to 1610 nm) on the same single fiber.

-

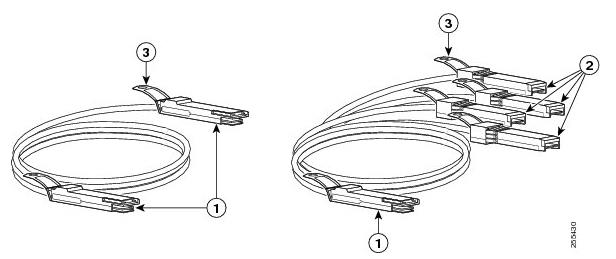

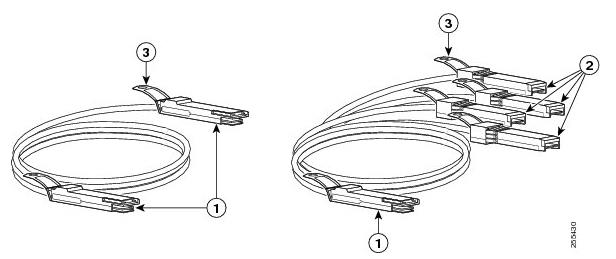

012019-10AOC is the abbreviation of Active Optical Cables, which is called Active Optical Cables in Chinese. AOC active optical is to encapsulate two optical modules and cable together. Because the medium of transmission in the middle is optical cable, AOC optical module, which contains laser devices, has a higher price for DAC. However, its optical aperture is not exposed, it has high reliability, and its working distance can be customized for a long distance of less than 100 meters.

-

012019-10Dense Wavelength Division Multiplexing (DWDM) technology is capable of transmitting data in an optical fiber using bit wavelength parallel transmission or string line transmission using the wavelength of the laser.It is widely used in different fields of communication networks, including long-distance backbone networks, metropolitan area networks (MANs), residential access networks, and local area networks (LANs).The DWDM optical module is the optical module that uses this technology, so the DWDM optical module has high bandwidth and long-distance transmission characteristics.